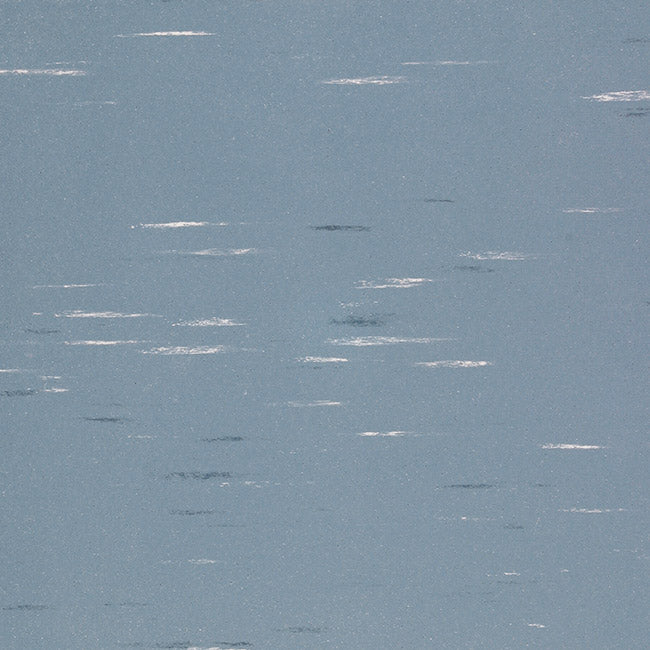

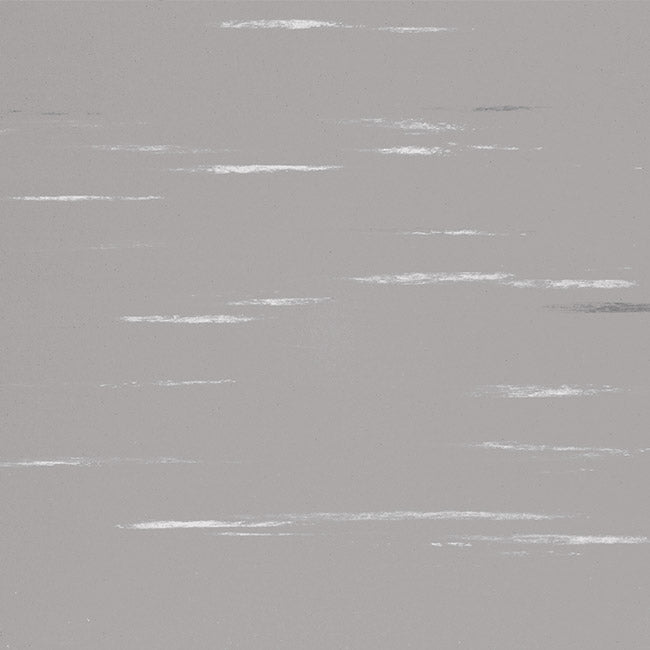

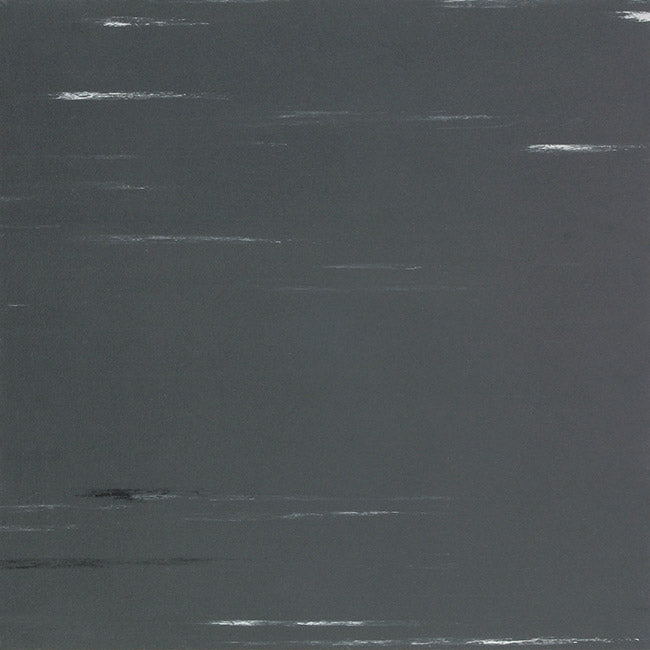

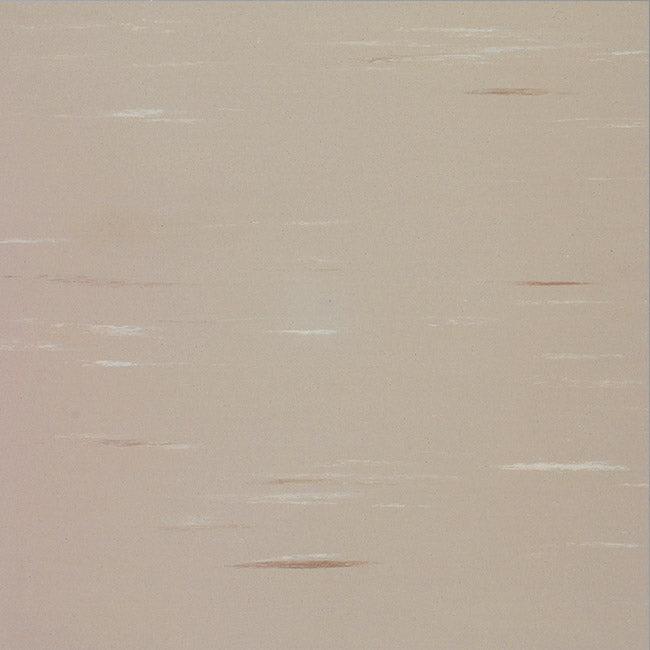

Unitile™

Unitile™ is a uniquely formulated homogenous tile available in 2mm and 2.5mm thicknesses. Due to its patent-pending formulation, Unitile is easy to specify due to its improved flexibility and competitive pricing. Ideal for classrooms, halls, passages, storerooms, you name it, Unitile™ can cover it.

Unitile™

PRODUCT BENEFITS

- The best of both with the look of Floorflex but with flexibility!

- Local manufacture

- Low carbon footprint

- Durable – dense smooth finish and proven performance in the market

- Sans 581 mark

- Composition 70% natural

- 100% recyclable

- Brand reputation – in the market for over 68 years

- Thru-Flash of marbling

- Not directly dependent on ROE

- Phthalate-free

- No restricted substances

- Class 1 Fire rating

- Continuity of supply

- Distribution capability – service level to market

- Direct delivery to site

- Representation (National footprint)

- NCS Coded

- 15-year warranty

- Technical support/back up

AREAS OF USE

- Commercial

- Office

- Schools

- Hospitals

- Hospitality

- Residential

PRODUCT INSTALLATION

- Unitile™, should be installed in accordance with manufacturer’s recommendations. Sub-floors must be smooth, hard, clean, and dry before laying commences.

- Uneven, solid or suspended timber floors may need preparation to meet the required standard.

- In case of direct to earth concrete, a damp proof membrane must be incorporated into the sub-floor.

- Unitile™ tiles must be allowed to relax for 24 hours in a uniform room temperature between 18°C and 27°C prior to installation.

- All sub-floors must be tested for moisture content prior to installation.

- The recommended adhesive for Unitile™ tiles is FloorworX No. 62 acrylic adhesive.

- It is essential that during the course of installation the material be rolled in both directions with an articulated 68kg three section metal floor roller.

SUGGESTED SPECIFICATIONS

- Supply and fit 2.0mm/2.5mm thick, 300mm x 300mm locally manufactured vinyl Unitile, laid in FloorworX No. 62 acrylic adhesive which has been spread using a trowel fitted with an A2 notched blade at a rate of between 5.5m2 and 6.5m2 per litre on a previously prepared Class 1 subfloor in accordance with SANS 10070, using a reliable Self Leveller when required, including all cutting and waste.

- The flooring must be rolled in both directions with an articulated 68kg three-sectional roller immediately after it has been laid into the adhesive. The newly laid floor must, after 48 hours, be stripped using FloorworX Stripper, scrubbed using a diluted solution of FloorworX Rinse and then sealed with 3 coats of FloorworX Sealer.

PRODUCT WARRANTY

FloorworX offers a 15 year limited warranty, subject to our terms and conditions, against defective material provided that it is installed and maintained in accordance with our recommendations.

PLEASE NOTE: This product is for indoor use ONLY.

PRODUCT MANTENANCE

Please refer to Cleaning & Maintenance under Technical.

PRODUCT STORAGE

STANDARD STORAGE PRACTICE

If an installation is large and material has to be stored on site, the following precautions should be taken:

- Storage area must be secure and away from other trades

- Storage area should be clean, dry and environmentally stable (18 ºC – 23ºC)

- Sheeting rolls should stand upright

- No heavy material should be placed on top of rolls or stacked boxes

Please Note: Temperature variations, excess weight or an uneven floor surface will distort the floor material. For more information please contact the FloorworX Technical Department by sending your query to technical@floorworx.co.za

Choose options

PRODUCT ENQUIRY

A PROUDLY SOUTH AFRICAN COMPANY

FOCUSED ON achieving sustainable progression

WE OFFER Top-notch support

AWARD-WINNING MANUFACTURER